NEWSLETTER

Please enter your email below to receive notifications about new products, special offers and discounts.

Boots on the Ground

June 2, 2022

Crafting combat footwear for the Vietnam War

THE YEAR WAS 1967, and the Vietnam War raged on. With half a million American troops in South Vietnam, the U.S. was at the height of its combat operations. One major challenge? The standard, all-leather boot issued to troops was falling apart. As America’s warfighters trudged through the dense bamboo, razor-sharp grass, and perilous swamps of southeast Asia, the stitching on their boots was rotting. The federal government sought a more reliable construction to withstand the hot, wet, and humid conditions troops encountered every day.

“When lives are on the line—as they were every day in the Vietnam War—no gear is more critical than durable combat boots.”

-Jim McRae, Vice President, Director, and Secretary of McRae Industries

Changing course

More than 9,000 miles away from Vietnam, in tiny Mount Gilead, NC, a children’s shoe company had a solution to the military’s boot problem. Gro-Rite Shoes built its footwear following “Process 82.” Instead of the standard practice of stitching on soles by using the welt construction, rubber outsoles were molded directly onto the leather, yielding a highly functional and long-lasting boot.

|

|

More than 9,000 miles away from Vietnam, in tiny Mount Gilead, NC, a children’s shoe company had a solution to the military’s boot problem. Gro-Rite Shoes built its footwear following “Process 82.” Instead of the standard practice of stitching on soles by using the welt construction, rubber outsoles were molded directly onto the leather, yielding a highly functional and long-lasting boot. |

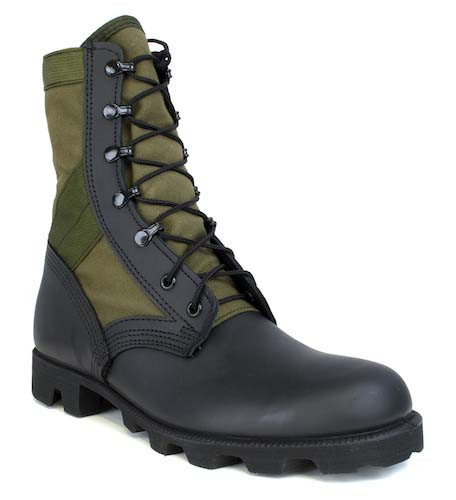

The U.S. Department of Defense asked Gro-Rite to consider producing combat boots for the Vietnam War. The company bid on and was awarded its first federal contract. The product: olive drab jungle boots, with a hunter-green canvas upper section and thick black rubber outsole. The war order secured, the company changed its name to McRae Footwear and swiftly exited the children’s shoe business. Although McRae shared the jungle boot contract with 13 other government suppliers, work was plentiful. Jungle boot construction continued steadily in Mount Gilead until 1973, when U.S. troops left Vietnam.

Building a relationship with the federal government

| “The military boot business was a huge change for us,” says Jim McRae, Vice President, Director, and Secretary of McRae Industries. “We had the equipment and we had the knowledge, but we needed to learn about government specifications and the ins and outs of being a government contractor.” |  Functional and long-lasting: Functional and long-lasting:McRae’s olive drab Jungle Boot |

Sparked by the abiding tenacity of company founder Branson McRae, the company continued making military boots of various designs for the government using the Vulcanizing/direct molded sole construction. Over the years, McRae has emerged as a trusted supplier of military boots.

The jungle boots were so successful that they remained a military-spec item until the mid-1990s. McRae still manufactures commercial versions of these boots using the same vulcanizing presses and molds from the Vietnam War era. Today’s boot is constructed of green canvas-colored nylon Cordura for light weight and maximum airflow.

“The Vietnam War had a huge impact on our nation,” Jim says. “It also had a huge impact on our family business. We started bidding for government contracts, and we have been fortunate ever since to continuously win government work.”

Responding to the call:

Responding to the call: